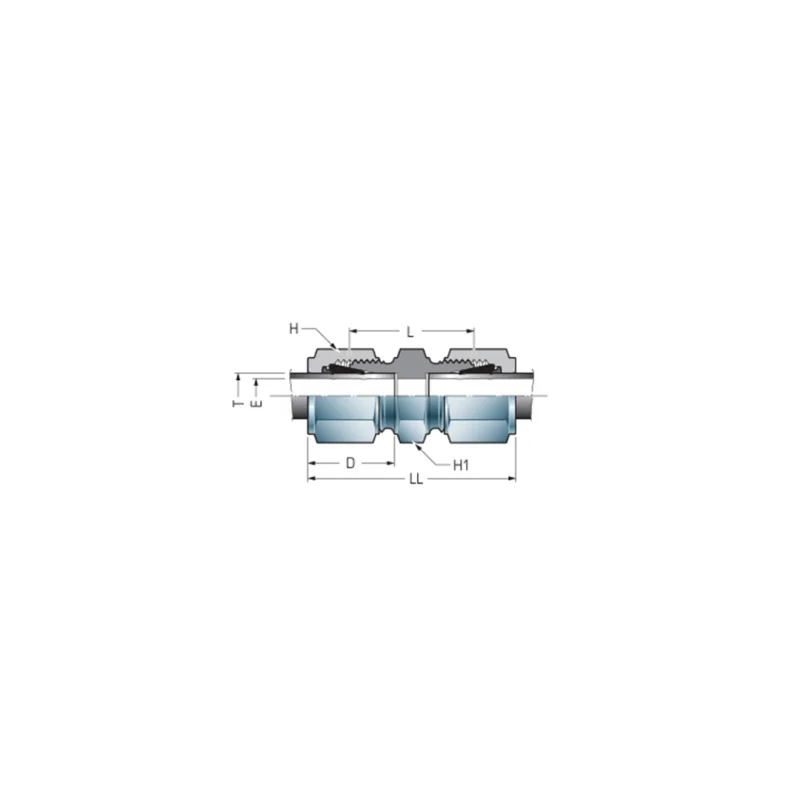

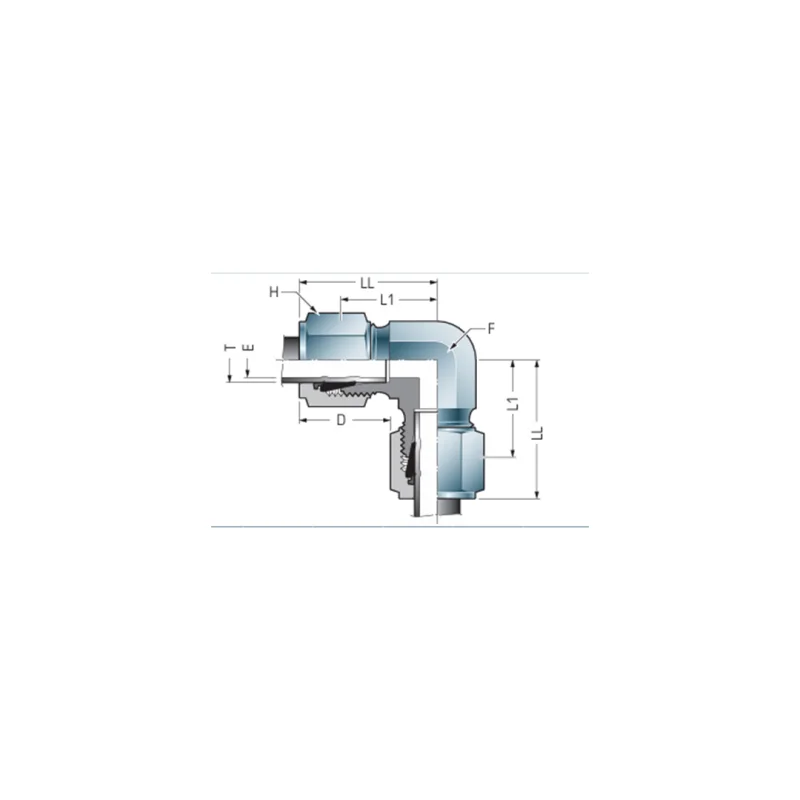

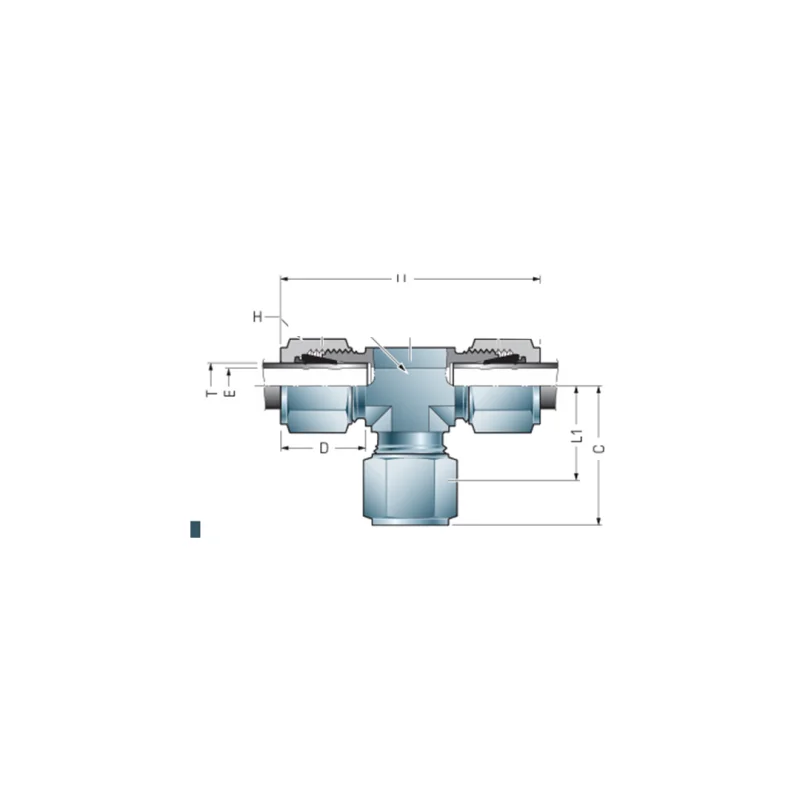

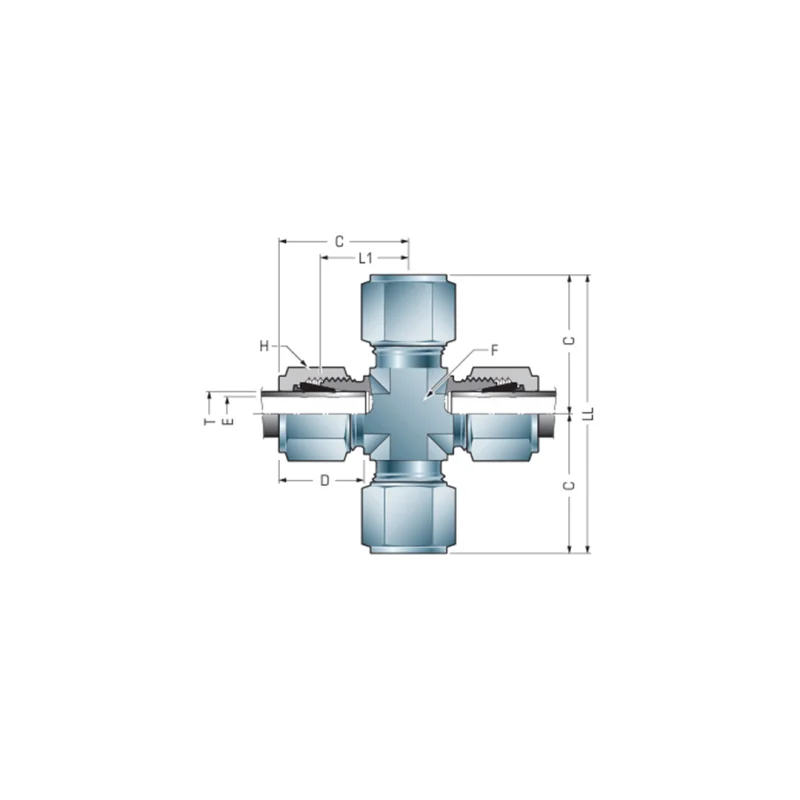

Double Ferrule Compression Fittings for Industrial applications

Reliable Solutions for reliable Connections

Double ferrule compression fittings are essential components for ensuring reliable and high-performance connections in industrial applications. Their double ferrule design provides excellent sealing even under high pressure and high temperatures. They are perfect for applications of chemical and petrochemical industries, power plants and process industries.

Their ability to withstand vibrations and mechanical stresses makes them indispensable in many industrial applications. We also offer custom-made fittings that perfectly fit specific technical requirements. Double ferrule compression fittings are easy to install and provide long-lasting durability, minimizing the need for maintenance. According to customer’s request compression fittings are manufactures on stainless steel (AISI 316, AISI 304), duplex stainless steel (F51, F53, F55) or other alloys ((Inconel 625, Inconel 825, Hastelloy C276, Monel 400, brass).

We and selected third parties use cookies or similar technologies for technical purposes and, with your consent,

also for other purposes as specified in the .

If you close this banner with a tick or click on "Decline", only technical cookies will be used. If you want to select the

cookies to be installed, click on 'Customise'. If you prefer, you can consent to the use of all cookies, including

cookies other than technical cookies, by clicking on "Accept all". You can change your choice at any time.