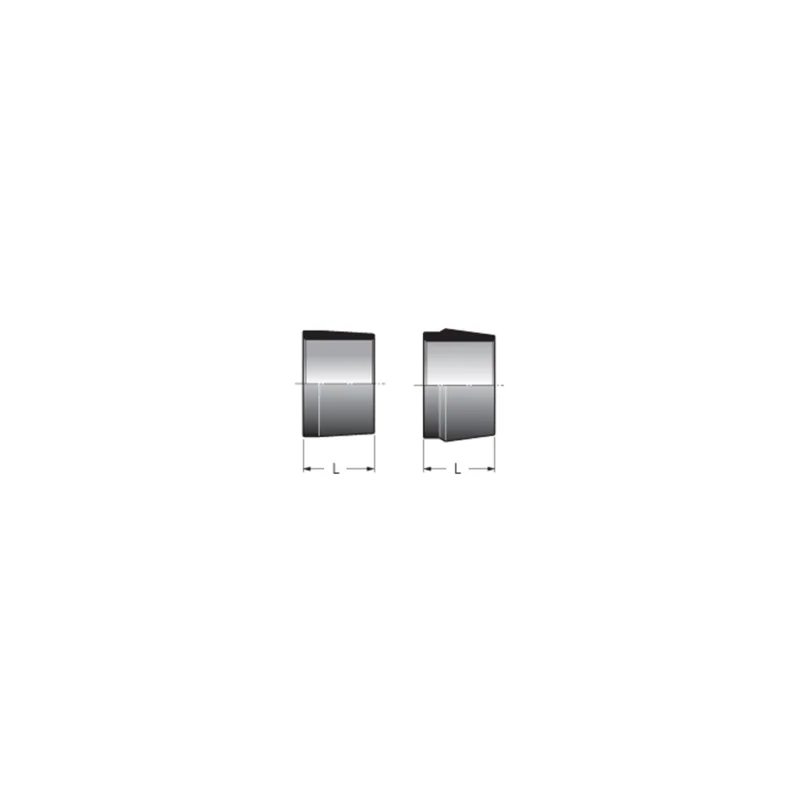

Single Ferrule Compression Fittings for Industrial applications

Manufacturer of Single Ferrule Compression Fittings for Reliable Connections

Single ferrule compression fittings are ideal solution for ensuring reliable and leak-proof connections for industrial applications where fluid containment and leak prevention are crucial. Simer offers single ferrule compression fittings production, designed to provide high performances even in heavy-duty conditions.

The single ferrule compression fittings are mainly used in low to medium-pressure applications, where connection reliability is essential. Thanks to their simple and robust design, single ferrule compression fittings ensure quick and safe installation, minimizing the risk of fluid leakage and providing proper operation of industrial plants. According to customer’s request compression fittings are manufactures on stainless steel (AISI 316, AISI 304), duplex stainless steel (F51, F53, F55) or other alloys ((Inconel 625, Inconel 825, Hastelloy C276, Monel 400, brass).

Trust Simer for production of single ferrule compression fittings, an economical and reliable solution for every type of application.

We and selected third parties use cookies or similar technologies for technical purposes and, with your consent,

also for other purposes as specified in the .

If you close this banner with a tick or click on "Decline", only technical cookies will be used. If you want to select the

cookies to be installed, click on 'Customise'. If you prefer, you can consent to the use of all cookies, including

cookies other than technical cookies, by clicking on "Accept all". You can change your choice at any time.