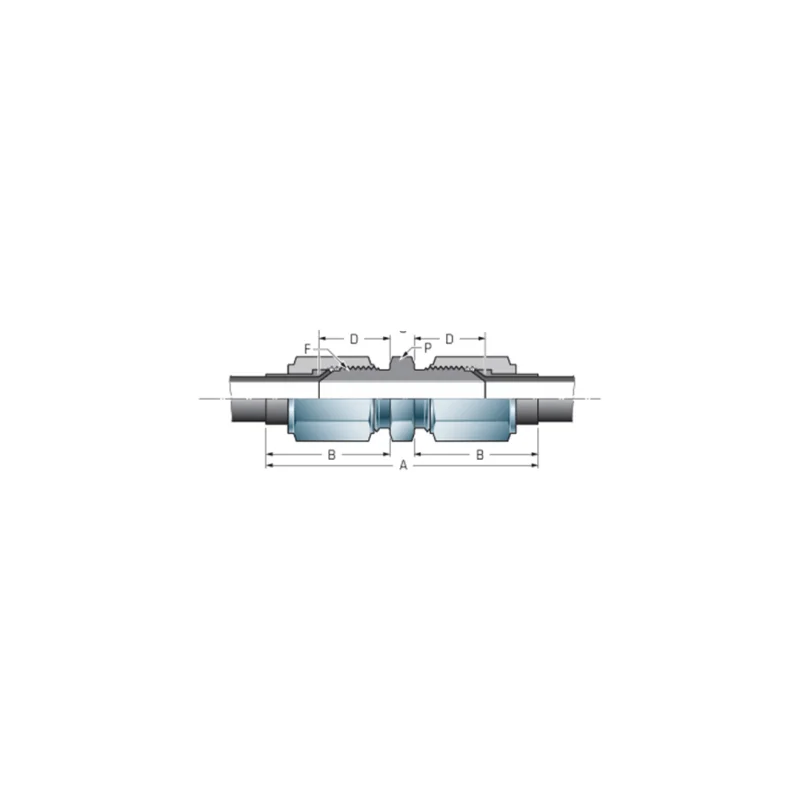

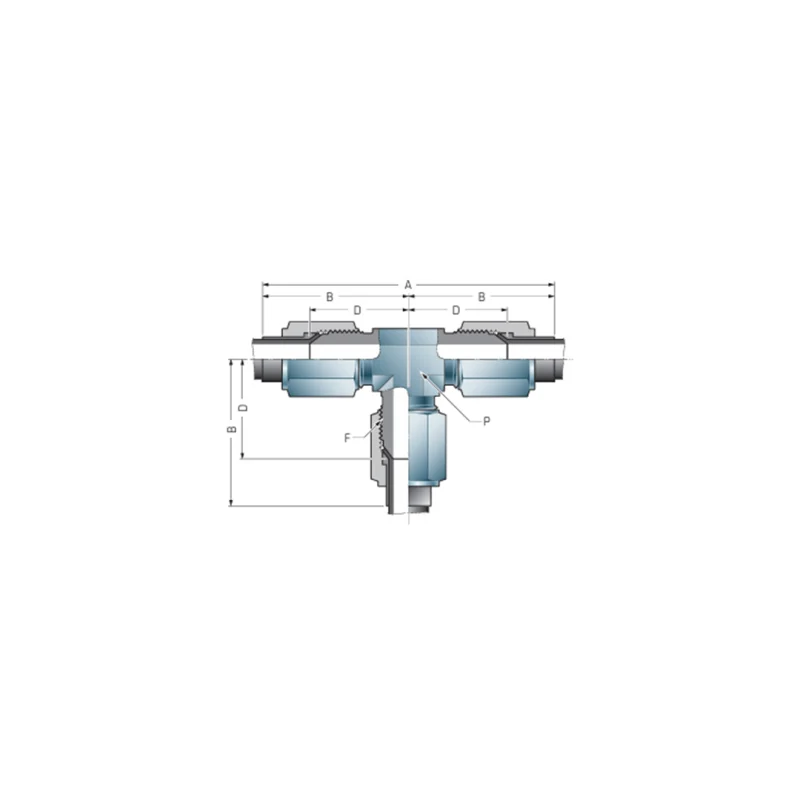

37° Compression fittings

Versatile Solutions for High-Reliability applications

37° compression fittings are a highly reliable solution for connecting pipes in industrial systems. Designed to provide an excellent performance, 37° angle of these fittings ensures a reliable and durable sealing effect, even in heavy-duty applications. Ideal for applications of chemical and petrochemical industries, power plants and process industries 37° compression fittings are made of high-quality materials, resistant to high pressures.

The manufacture of 37° compression fittings is tailored to meet the specific technical requirements of each customer, offering both customized and standardized solutions. These fittings are easy to install and ensure perfect compatibility with existing systems, reducing maintenance time and maximizing operational efficiency. According to customer’s request compression fittings are manufactures on stainless steel (AISI 316, AISI 304), duplex stainless steel (F51, F53, F55) or other alloys ((Inconel 625, Inconel 825, Hastelloy C276, Monel 400, brass).

We and selected third parties use cookies or similar technologies for technical purposes and, with your consent,

also for other purposes as specified in the .

If you close this banner with a tick or click on "Decline", only technical cookies will be used. If you want to select the

cookies to be installed, click on 'Customise'. If you prefer, you can consent to the use of all cookies, including

cookies other than technical cookies, by clicking on "Accept all". You can change your choice at any time.